What is Fatek HMI?

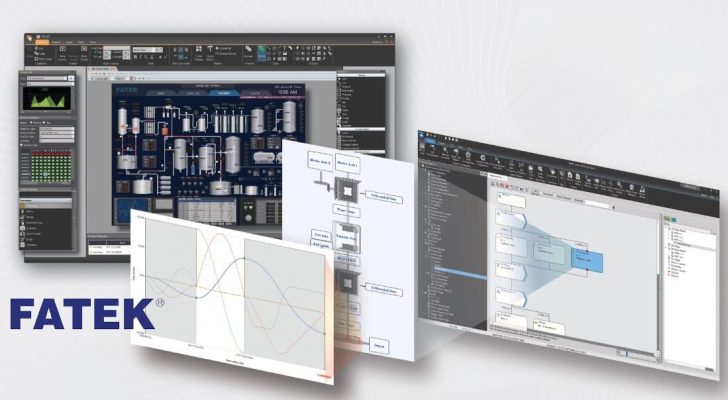

Fatek HMI refers to the Human-Machine Interface (HMI) devices manufactured by Fatek Automation Corp., a company based in Taiwan. HMI devices are used in industrial automation systems to provide a graphical interface for operators to interact with machines and monitor/control various processes.

Fatek HMI devices are designed to facilitate the operation and monitoring of industrial equipment and processes. They typically feature touchscreens, function keys, and communication ports to connect with other automation components such as programmable logic controllers (PLCs) or other devices on the factory floor. The HMI software allows users to create and configure visual displays, alarms, data logging, and other features necessary for effective process control.

Mechanism of operation of Fatek HMI

The mechanism of operation of Fatek HMI (Human Machine Interface) involves several key components and processes that enable it to function effectively in industrial automation systems. Here’s an overview of the typical mechanism of operation:

User Interface Design

The first step in operating a Fatek HMI involves designing the user interface. This includes creating screens, adding graphical elements such as buttons, sliders, indicators, and text, and arranging them in a way that makes it intuitive for operators to interact with the system.

Data Acquisition

Fatek HMIs acquire data from various sources such as PLCs (Programmable Logic Controllers), sensors, and other devices connected to the automation system. This data includes process variables, equipment status, alarms, and other relevant information.

Data Processing

Once the data is acquired, the Fatek HMI processes it to perform tasks such as filtering, scaling, and calculation. This processing ensures that the data is presented to operators in a meaningful and useful way.

Display and Visualization

Processed data is then displayed on the touchscreen interface of the Fatek HMI. The HMI uses graphical elements such as charts, graphs, meters, and animations to visually represent the data, making it easier for operators to understand the system’s status and performance.

User Interaction

Operators interact with the Fatek HMI by touching the screen to input commands, adjust setpoints, acknowledge alarms, and perform other control actions. The HMI responds to these inputs in real-time, updating the display and sending commands to connected devices as necessary.

Communication with External Devices

Fatek HMIs communicate with external devices such as PLCs, SCADA systems, and other HMIs using various communication protocols such as RS-232, RS-485, Ethernet, and USB. This communication allows the HMI to exchange data with other components of the automation system and control industrial processes.

Alarm Handling and Event Logging

Fatek HMIs monitor the system for abnormal conditions and generate alarms when predefined thresholds are exceeded or when specific events occur. Operators can view and acknowledge these alarms on the HMI interface, and the HMI may also log alarm events for further analysis and troubleshooting.

Remote Access and Monitoring

Some Fatek HMIs support remote access functionality, allowing operators to monitor and control industrial processes from a central control room or even via mobile devices. This enables operators to respond to changes in the system quickly and efficiently, regardless of their location.

Choosing a reputable Fatek HMI supplier

- Experience and reputation. Prioritize choosing a supplier with many years of experience in the field of providing and integrating automation systems, especially systems using Fatek HMI Screens. Evaluate the supplier’s reputation through criteria such as: recognized brand, implemented projects, customer feedback, etc.

- Fatek HMI expertise. Ensure the supplier has a team of highly specialized technicians who are knowledgeable about Fatek HMI Screens and related products. Ability to provide total solutions, including consulting on appropriate product selection, programming, installation, maintenance and technical support.

- Ability to provide genuine products. Committed to providing genuine Fatek HMI Screen products, with clear origin and full certification documents. Continuously update the latest versions of products to meet market needs.

- Competitive price. Compare prices from many suppliers to choose the most reasonable price. Be sure to consider price along with product quality, support services and accompanying incentives.

- Professional support service. Ensure the supplier provides professional, dedicated and fast customer support. Have a clear, transparent warranty policy and timely technical support when customers encounter problems.

Force to choose providing Fatek HMI, reputable in the market

- Reliability: Fatek HMIs are known for their reliability and robustness in industrial environments. They are designed to withstand harsh conditions, ensuring consistent performance and longevity.

- Quality: Fatek products are manufactured to high-quality standards, adhering to strict quality control processes. This commitment to quality has earned them the trust of customers across various industries.

- Innovation: Fatek continuously invests in research and development to innovate and improve their products. They regularly introduce new features and technologies to meet the evolving needs of industrial automation.

- Compatibility: Fatek HMIs are designed to be compatible with a wide range of PLCs, controllers, and other industrial devices, providing flexibility and ease of integration in automation systems.

- Support and Service: Fatek provides comprehensive support and service to their customers, including technical assistance, training programs, and product documentation. This ensures that customers can effectively deploy and maintain Fatek HMI systems

Communications

FATEK VIETNAM COMPANY

Website: https://fatek.com.vn/

Hotline: 097 523 9823

English

English Français

Français 中文 (中国)

中文 (中国) 日本語

日本語 한국어

한국어