Servo Fatek – The perfect automation solution for every application

- Manufacturing industry: Fatek servo is used to control robots, CNC machines, assembly lines and many other automation devices.

- Packaging industry: Servo Fatek ensures high precision in packaging, labeling and product shipping processes.

- Solar industry: Fatek servo effectively controls solar tracking systems, optimizing energy harvesting performance.

- Textile industry: Servo Fatek precisely controls weaving, sewing, and embroidery machines, ensuring high product quality.

- And many other industries: Servo Fatek can be applied in many different fields thanks to its flexibility and high efficiency.

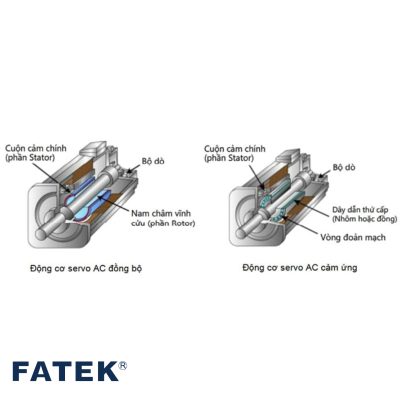

Mechanism of action of ervo Fatek

Power conversion

-

The servo drive receives AC or DC power from the mains supply. Internal power electronics convert this raw power into precisely regulated DC voltage and current, tailored to drive the specific servo motor connected to it.

-

Command reception: The drive receives control commands from the control system (PLC) or Servo Studio SD3 Fatek software. These commands specify the desired motor behavior, whether it’s achieving a precise position, maintaining a specific velocity, or exerting a particular torque.

-

Encoder feedback: The servo motor incorporates a built-in encoder, which constantly monitors its actual position (shaft angle or rotations). This crucial feedback signal is transmitted back to the servo drive, providing real-time data on the motor’s movement.

-

Control loop, this loop continuously compares the reference command (target position/velocity/torque) with the actual feedback received from the encoder. The difference between these values, termed the control error, is vital for corrective action.

Gain adjustments for optimal performance

-

- Servo Studio SD3 Fatek software empowers users to configure proportional, integral, and derivative (PID) gains. These gains significantly influence how the servo drive adjusts its output based on the control error.

- By fine-tuning these gains, you can optimize the control loop’s response, leading to smoother motion control, improved accuracy, and faster response times for your application.

-

Pulse ưidth modulation (PWM): Delivering precise power:

- Based on the control error and configured gains, the servo drive generates a Pulse Width Modulation (PWM) signal. This signal essentially controls the average voltage delivered to the motor’s windings.

- A higher pulse width signifies a longer “on” time for the current flow, delivering more power to the motor. Conversely, a lower pulse width translates to less power.

-

Motor driver, the bridge between control and action. It amplifies the PWM signal and regulates the current supplied to the motor windings based on the control loop’s output. By adjusting the current and its direction, the driver effectively controls the motor’s rotational speed and direction.

Choosing the right Fatek Servo: Detailed instructions for each need

- Servo size and weight: Fatek servo comes in many different sizes and weights, suitable for many types of machinery and equipment.

- Servo motion range: Determine the required motion range for your application to select a servo with the appropriate travel.

- Servo speed and torque: Fatek servo offers a wide range of speed and torque levels, meeting the performance requirements of the application.

- Servo accuracy: Select a servo with accuracy appropriate to the position and speed error requirements of the application.

- Servo operating environment: Servo Fatek is capable of operating in many different environments, including dusty, humid and high temperature environments.

- Your budget: Servo Fatek comes in a variety of price ranges to fit your budget.

Why should you choose Vnatech as your Fatek servo supply for automation systems?

Selecting Vnatech as your Fatek servo supply for automation systems can offer several advantages:

- Expertise and Experience: Vnatech may have extensive expertise and experience in the field of industrial automation, including the integration and application of Fatek servo systems. Their knowledge can help ensure that you receive the most suitable servo solutions for your specific needs.

- Product Range: Vnatech may offer a wide range of Fatek servo products, allowing you to choose from various options based on your application requirements, such as different power ratings, sizes, and features.

- Quality and Reliability: Vnatech may prioritize quality and reliability in the products they supply. Fatek servo systems are known for their robustness and durability, contributing to long-term performance and minimal downtime in your automation systems.

- Technical Support: Vnatech may provide excellent technical support and assistance throughout the selection, installation, and operation of Fatek servo systems. This support can be invaluable in troubleshooting issues, optimizing performance, and maximizing the efficiency of your automation processes.

- After-Sales Support: Vnatech may offer reliable after-sales support, including warranty services, maintenance, and spare parts availability. This ensures that you have ongoing assistance and resources to address any issues or concerns that may arise after the initial installation.

- Customer Satisfaction: Vnatech may prioritize customer satisfaction by offering responsive communication, timely delivery, and a commitment to meeting your needs and expectations. Their focus on customer satisfaction can contribute to a positive experience throughout your partnership.

Communications

FATEK VIETNAM COMPANY

Website: https://fatek.com.vn/

Hotline: 097 523 9823

English

English Français

Français 中文 (中国)

中文 (中国) 日本語

日本語 한국어

한국어