AUTOMOBILE PRODUCTION LINE

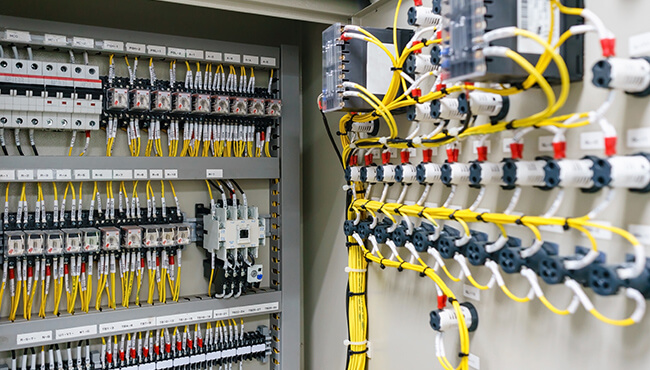

The automobile industry is an integrated industry developed based on many peripheral industries and related technologies. In addition to the complex and precise control performance requirements for controllers, their environmental resistance and reliability are also extremely essential in the manufacturing process. During the body shell stamping process, mutual precision is required to ensure uniform thickness. The production line’s conveyor belt must operate smoothly and have good stability so that parts do not come loose during assembly. In the paint room, temperature control is very strict. Incorrect heating can cause paint defects. In the assembly area, reliable test fixtures and an easy-to-operate and stable human-machine interface are needed to assist people in assembly.

FOOD INDUSTRY

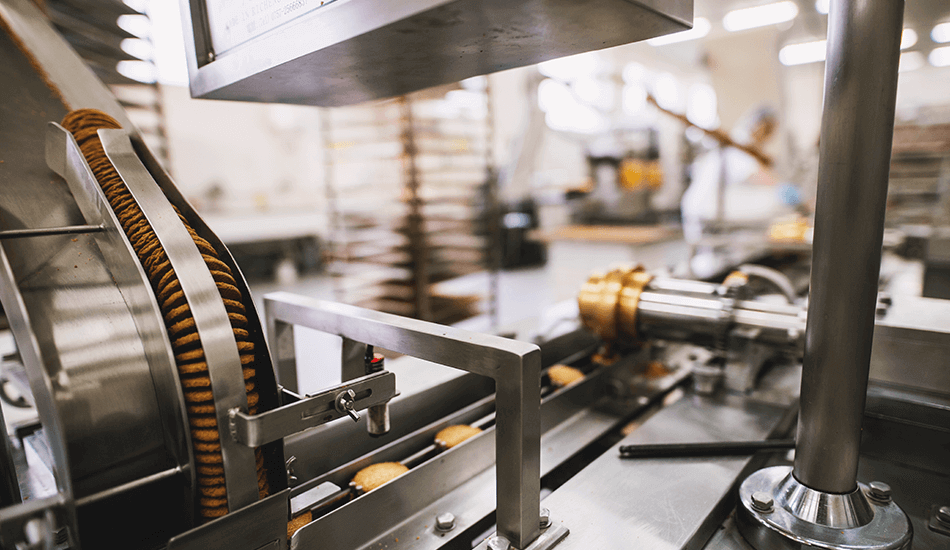

Food preparation methods are extended from the chef’s hands in the kitchen to automatic production equipment in the central kitchen. Cooking for the same taste and flavor as the base cooked by the chef can only be achieved by adjusting each production parameter and monitoring every detail with a stable controller. The dough rolling machine must work accurately and synchronously with many axes to roll the dough evenly. Container injection equipment must respond quickly to accurately control pump capacity. The heating system must be capable of precise temperature control to get the desired flavor. Then, the packaging machine will quickly wrap the food to ensure the freshness of the food ingredients is maintained.

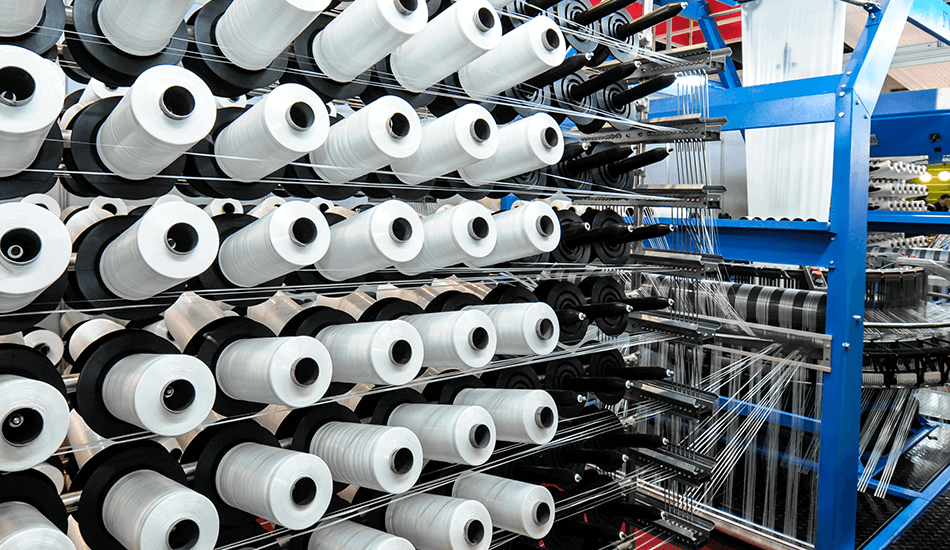

TEXTILE INDUSTRY

Textile production can be carried out not only for sewing clothes. Through intricate layer-by-layer weaving and stacking techniques, it can also be made into some beautiful, picturesque multi-layered crafts. With the advancement of industrial automation, today, we can also create beautiful clothes using looms, something that previously only skilled tailors could do. Okay. Tangled fibers need to be loosened by rolling, beating, pulling and tearing. However, the controller must continue to operate stably by resisting noise and vibrations from complex environments. The weaving process depends on weaving the fibers very quickly. It has high performance and precision requirements for the controller. During the dyeing and finishing process, it is necessary to heat chemicals to mix and create color. Color fastness must be performed after dyeing. During this process, precise temperatures are needed to ensure the dye is firmly attached to the various materials.

Tiếng Việt

Tiếng Việt Français

Français 中文 (中国)

中文 (中国) 日本語

日本語 한국어

한국어