With outstanding features, HMI Fatek software helps manufacturing businesses optimize processes, improve labor productivity, reduce errors and risks, and improve decision-making based on accurate data.

About HMI Fatek Software

Definition and role of HMI Fatek software

- HMI software is a programming tool used to design and develop human-machine interfaces (HMIs) for monitoring and control applications.

- Fatek HMI software is used to program and design interfaces for HMI devices manufactured by Fatek, allowing the integration of graphical components, charts, reports, and dynamic data.

- With HMI software, users can easily create a friendly, intuitive interface.

- Help monitor and control production processes, machines remotely.

History of development and birth of HMI Fatek software

- Fatek is a company from Taiwan, specializing in manufacturing industrial automation products such as PLC, HMI, Servo driver.

- Fatek’s first HMI software came out in the 1990s to support programming for its HMI devices.

- Over the years of development, new versions of HMI software with nicer interfaces and superior features were launched such as HMIEdit, HMIShop, HMISoft

The importance of HMI Fatek software application in modern manufacturing

- HMI software helps reduce the time and cost of developing monitoring and control systems.

- Create a friendly, intuitive interface that improves operational and production efficiency.

- Simplify the processes of manipulation, operation of complex machines and equipment.

- Allows connecting, integrating data from many different sources together.

- Improve the ability to analyze, track and report production data.

- In line with the trend of industry 4.0, high automation in modern production.

Thanks to HMI Fatek software, the design and implementation of automatic monitoring and control systems has become easier, faster and more efficient, playing an important role in today’s industrial manufacturing plants.

Outstanding features of HMI Fatek software

User-friendly interface, easy to use

- Beautiful, modern, intuitive graphical interface

- Design support by dragging and dropping graphic objects

- Provides many convenient drawing and image editing tools

- Multilingual support, easy interface changes

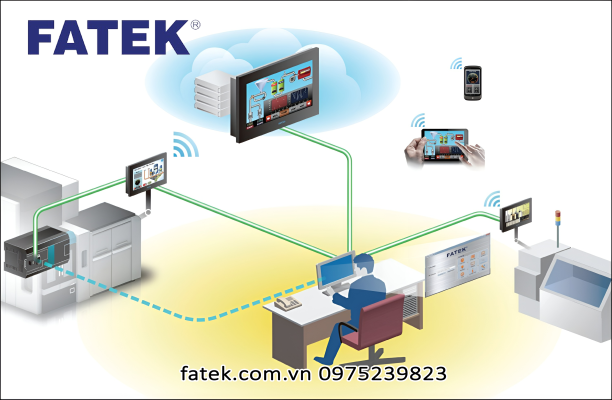

Interoperability and monitoring of the production process

- Real-time dynamic data visualization

- Warnings, operating status indicators

- Trend charts, graphs that simulate the process

- Automated scheduling and reporting of the production process

Integration with other devices and systems

- Connect to PLC, PAC, Servo and Fatek devices

- Integration with SCADA, ERP, MES, and 3rd party software

- Supports multiple communication protocols such as Modbus, Ethernet/IP

- Connect via USB, Ethernet, Serial ports

High programmability and customization

- Provides many available programming objects

- Allows customizing graphics, advanced animations

- Support many programming languages such as C, VB Script, JAVA

- Has a rich library of functions and object classes

In addition, HMI Fatek software also has many other features such as account management, activity log, data export/import, database,…

With diverse and powerful features, HMI Fatek has become an effective programming tool, making it easy for manufacturers to develop professional automation monitoring and control systems.

HMI Fatek software application in manufacturing

The field of production is suitable for HMI Fatek software

- Mass production plant (food, beverage, pharmaceutical,… processing)

- Automobile and electronic assembly plants

- Factory producing building materials (cement, bricks, tiles, glass,…)

- Mechanical enterprises manufacturing machinery and equipment

- Chemical Manufacturing and Processing Plant

- Energy plants (thermal power, wind power, hydropower,…)

<h3>HMI Fatek software application

- Bottled Food Production Line Monitoring

- Control of yarn looms at the textile factory

- Management of cement mixing and packing process at concrete plant

- Monitoring and reporting output at mechanical processing plants

- Control the incinerator system at the chemical plant

- Monitoring and warning of wind turbine system condition

Benefits and impact when applying HMI Fatek software

- Improve production efficiency and productivity thanks to accurate process monitoring and control

- Save operating labor costs, minimize risks for people Improve product quality, reduce defects thanks to strict control

- Simplify complex machine operations

- Increase the ability to detect and handle problems in a timely manner

- Track and record the history of production data for analysis and improvement

- Improve product traceability Easy to expand, upgrade the system as needed

HMI Fatek software implementation and integration

In order to successfully deploy and integrate HMI Fatek software, it is necessary to follow the correct process, meet the requirements of infrastructure and human resources, and have a training and technical support plan for users.

HMI Fatek software implementation and integration process

- Clearly define the requirements and objectives of the project using HMI

- Choose the right HMI Fatek software (HMIEdit, HMISoft, HMIShop,…)

- User interface design with HMI software

- Program monitoring and control functions for the interface Install HMI software on a computer/device running

- Establish a connection between HMI and other devices (PLC, Servo,…)

- Testing, commissioning and calibration of HMI systems

- Deploy operation and actual monitoring with HMI system Maintain, update and expand the system as needed

Infrastructure and human resource requirements

- Computer or HMI device suitable for software installation

- LAN infrastructure to connect HMI to other devices COM, Ethernet, USB connectors for communication with PLC, Servo ,…

- Technical manpower with knowledge of PLC programming, automatic control

- Software engineer or programmer to design HMI interfaces

- System Integration Specialist for Project Implementation

Training and technical support for users

- Organize training on how to use HMI software for operators

- Guide to make good use of the features and tools of the software

- Provide detailed HMI software documentation

- Set up a technical support hotline for users

- Update patches, new versions of software

- Advanced training on HMI development and programming for technical staff

By following the correct process, fully preparing infrastructure, human resources and having appropriate training and support plans, HMI Fatek deployment and integration will be the most successful and effective.

Trends and the future of HMI Fatek software

- 3D interface, more vivid graphic effects

- Integrate virtual reality (VR/AR) technology for a deeper interactive experience

- Supports display on many different types of screens, including curved, large screens

- Support more advanced industry protocols such as OPC UA, MQTT

- Easy integration with cloud computing systems, IoT

- Connect and synchronize data with large databases, SCADA/MES applications

- Mobile HMI version, information synchronization

- Web-based interface for remote monitoring and control over the network

- Provide open framework for library development, extension modules

- The programming IDE integrates more utility development tools

- Ability to embed code, 3rd party applications into HMI

Please contact us immediately to receive professional advice and the optimal solution for your needs!!

Contact Info

FATEK VIETNAM COMPANY.

Website: https://fatek.com.vn/

Phone number: 097 523 9823

English

English Français

Français 中文 (中国)

中文 (中国) 日本語

日本語 한국어

한국어